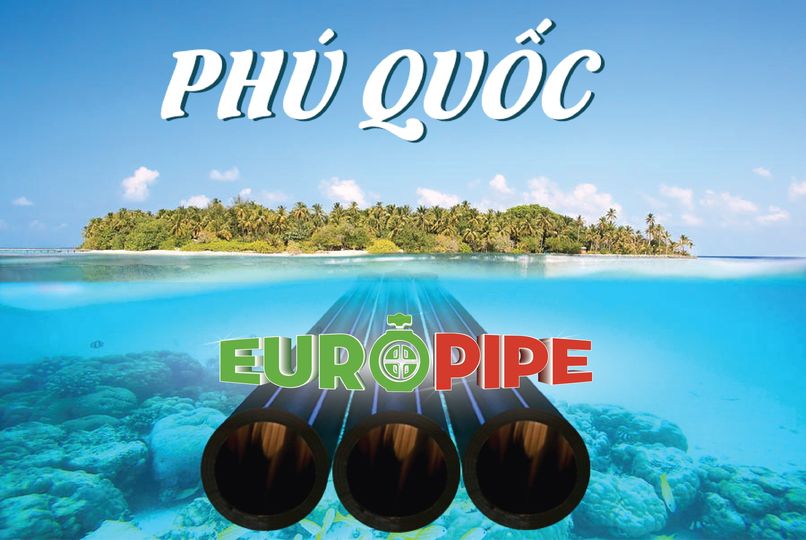

EUROPIPE provides large-sized plastic pipes for a rare project in Vietnam – Seawater Supply Pipeline Project – Phu Quoc Seawater Pumping Station. This is a special project because it is carried out on the sea and islands with many harsh conditions: seawater environment, complex terrain, weather, etc.

The EUROPIPE process provided the plastic pipe for this particular project

Before choosing EUROPIPE as a supplier of materials to carry out this project, the investor and contractor spent a lot of time researching products and looking for suppliers and domestic manufacturers. But only when approaching EUROPIPE, the requirements of technical standards and progress are met, and the project can be started.

On EUROPIPE’s side, when receiving the delivery of DN900 PN16 and DN1200 PN12.5 pipes, the company knew that the problem to be solved was a super-rare pipe, almost never appeared on the market with the standard size and special degree of precision. wall thickness up to 81.7mm – 97.2mm. However, from the methodical investments, equipment, and people who are always ready, EUROPIPE has quickly deployed production and successfully supplied.

The reason that EUROPIPE was chosen to provide plastic pipes for the project

The promotion of the strengths of EUROPIPE can be summarized in the following main points:

Firstly, with this particular product, EUROPIPE has the advantage of being a mold factory located in a factory system of more than 10 hectares, ready to make all “tailored” products according to all customer requirements row.

The larger the production requirements, the higher the compatibility, ie the greater the complexity of the details, leading to more modern and precise requirements for the mold maker and the machine system…

Secondly, EUROPIPE always uses the world’s best raw materials branded Boruoge of the UAE in the production of plastic pipes. This is a primary plastic with top quality in the world, transported in bulk to EUROPIPE’s warehouse for preservation, ensuring supply whenever the factory has production demand.

The production process of HDPE pipes at EUROPIPE Factory starts with putting raw materials into drying at 90 degrees Celsius and dehumidifying them almost completely before going through the dosing system to run in the extruder. Using such high-quality materials allows EUROPIPE to easily adjust and increase the melting temperature of plastic …, avoiding the case of uneven plastic particles leading to difficult manipulation, and lack of stability in the pipe wall.

Third, EUROPIPE has a system of machinery invested synchronously from Germany’s Battenfeld-Cincinnati brand – the world’s No. 1 brand of extruders.

During the heating process, thanks to a modern extruder system with good structure and high accuracy, the heat level is stabilized at only 165-180 degrees Celsius, much lower than the normal pipe running temperature in other systems. other. At this temperature, the extruder system is required to have more modern technology and a better structure than conventional extruders. Moreover, the automatic control mode through the electronic board of this system helps to quantify the plastic, plasticize and make the plastic flow evenly during the extrusion process, thereby ensuring the uniform wall of the pipe.

The finished plastic pipe, when running out of the extrusion rig, still retains a lot of heat, so a cooling system is needed to ensure the product cools down so that the pipe wall does not deform. EUROPIPE factory installed up to 6 large-capacity central indoor units, reaching 800 Kw/h, maintaining the cooling water temperature at 16-18 degrees Celsius while improving the cooling system in the pipe.

As a result, manufactured products always ensure the right quality and technical standards of DN900 PN16, and DN1200 PN12.5 codes, both in diameter and pressure level. In addition, the factory is also equipped with a special cutting machine that is specially machined, ensuring a smooth and beautiful cut without affecting the pipe wall, even though the pipe thickness can exceed 90mm.

Fourth, EUROPIPE always has a team of foreign experts to monitor the quality, and handle difficult situations that arise, especially when running large, high-pressure pipes with a thickness of up to 81.7mm – 97, 2mm like DN900 PN16, DN1200 PN12.5 which is extremely difficult to adjust and heat.

In the production process, the selection of tube extrusion mode and adjustment so that the finished product is not affected by factors that change the texture as well as appearance and quality is the most important thing. To do so, it is necessary to have a supervisor with high expertise, who works rigorously, and always puts the quality goal on top. This is another advantage of EUROPIPE, because the factory has European experts and a team of engineers and skilled personnel, helping the production process to go smoothly.

In fact, the production of plastic pipes of particular sizes and pressure classes such as DN900 PN16, a thickness of 81.7mm – 90.6mm, and DN1200 PN12.5 thickness of 88.2mm – 97.2mm brings more challenges. favorable for all manufacturers. But EUROPIPE succeeds by quickly solving these difficult problems.

Careful calculation in each step of manufacturing products with difficult and specific techniques, but also ready to accept challenges and break the limits in the manufacturing industry of large-thickness plastic pipes in Vietnam, DN900 PN16, DN1200 PN12.5 is EUROPIPE’s affirmation of the goal of “always there when the customer needs it”. With EUROPIPE, nothing is impossible, and conquering pipes DN900 PN16, and DN1200 PN12.5 shows the ability of the plastic giant to meet market requirements to an unlimited extent.

Tiếng Việt

Tiếng Việt