GENERAL FEATURES

- European Green inch uPVC pipe (EuroPipe): manufactured according to TCCS 311/2019 - TCVN 8491/2011.

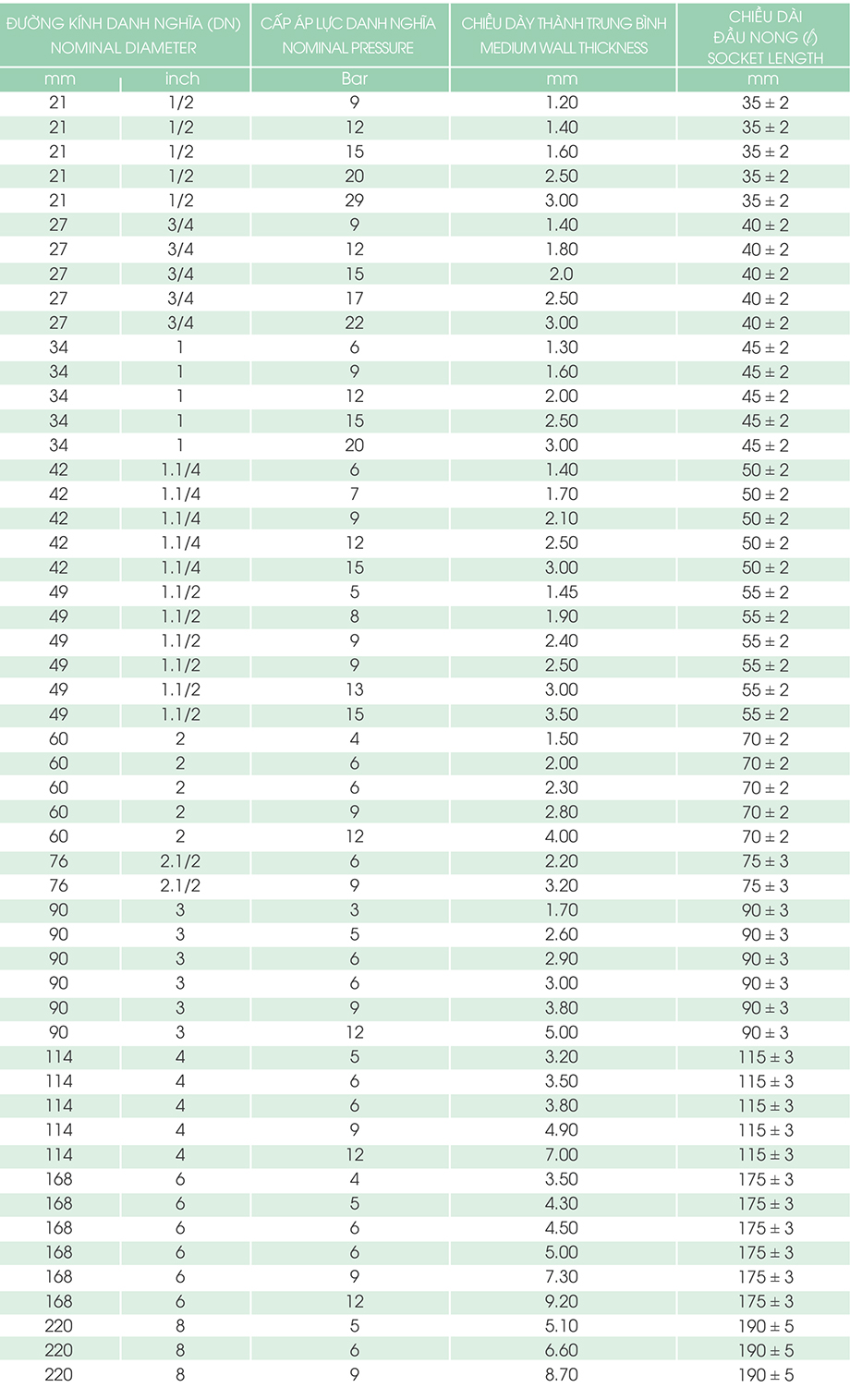

- Working pressure: 3 - 29 bar.

- Quality standards: The entire production process of EuroPipe is strictly controlled by the quality management system ISO 9001:2015.

OUTSTANDING PROPERTIES

European Green uPVC pipes are widely used in construction, water supply and drainage, and some industrial fields, due to many advantages:

- Light, easy to transport. Simple installation.

- Smooth pipe surface, small coefficient of friction for good drainage.

- Large mechanical surface, resistant to impact and high pressure.

- No rust, resistant to chemicals.

- Non-toxic.

- Reasonable price.

APPLICATIONS

- Light, easy to transport, and simple to install.

- Smooth pipe surface, small coefficient of friction for good drainage.

- Great mechanical strength, resistant to impact and high pressure.

- No rust, resistant to chemicals.

- Non-toxic.

- Reasonable price.

INSTALLATION SOLVENT WELD JOINT

1. Cut the pipe

If it is necessary, cut the pipe to the desired length with pipe cutters, hacksaw, or crosscut saw. make sure the cut is square.

2. Clean

Chamfer the cut ends and remove all the burrs of pipe with a knife-edge, file, or deburring tool. Make sure all joining surfaces are free from dirt, dust, water, and oil. Mark the pipe end with a socket depth line.

3. Coat

Coat the inside of the socket of the fitting with a medium layer of cement. Immediately. Apply a full even layer of cement on the pipe for a distance slightly greater than the. Depth of the fitting socket. If the cement dries on either surface before joining, apply another coat.

4. Join

Hold the pipe and fitting together firmly in position for 30 seconds (dn <63mm) or 30 seconds (dn 75mm - dn 250mm). Wipe the excess cement from the joint after assembly.

5. Test shall

Do not take the next step until the joint is cured. The hydrostatic pressure test shall be made only after 24 hours.

INSTALLATION GASKETED JOINT

1. Clean and dry

Clean and dry the inside of the bell and the outside of the spigot end of the pipe. Mark the spigot end with a socket depth line. Chamfer the spigot end of the pipe

2. Clean and dry the gasket

Clean and dry the gasket. Put the gasket into the bell groove.

3. Apply lubricant

Apply lubricant on the spigot end of the pipe and the surface of the gasket. The lubricant shall be nontoxic and shall have no deteriorating effects on the gasket and pipe materials.

4. Insert the beveled spigot end

Insert the beveled spigot end into the bell with a pulling tool until its contacts the gasket. Push the spigot end in until the reference mark on the spigot end is flush with the end of the bell. If undue resistance to insertion of the beveled end is encountered or the reference mark does not reach the flush position, disassemble the joint, check the position of the gasket, and remove any debris.

Tiếng Việt

Tiếng Việt